SERVICES

We offer a wide range of services. From design to production, we can get the job done.

PLASMA CUTTING

MACHINING

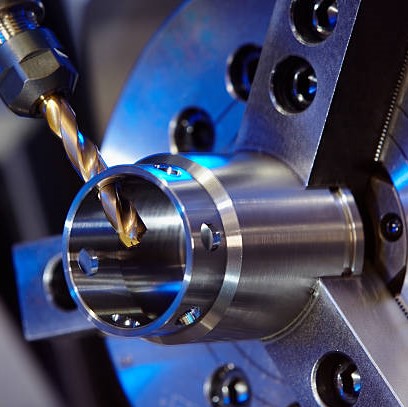

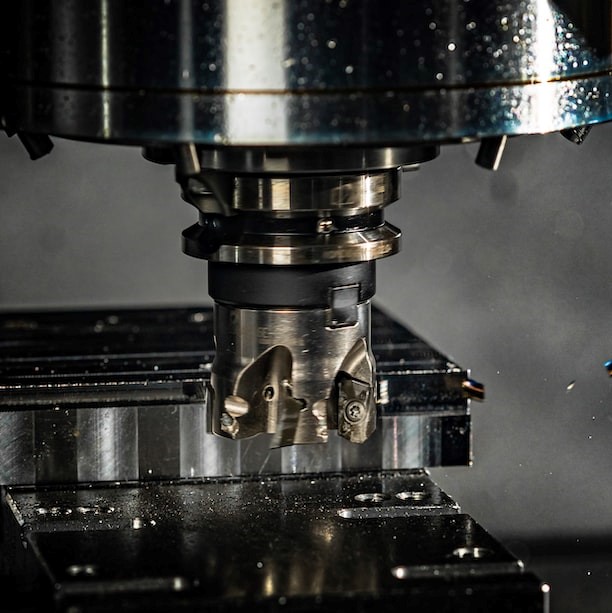

TURNING AND MILLING

Machining is a general term that encompasses various techniques used to shape, cut, or form metal using a wide array of tools and machines, such as lathes, drills, and grinders.

Milling and turning are machining processes used to remove material from a workpiece to create specific shapes or features. Milling involves rotating cutting tools to remove material from the workpiece, while turning uses a stationary cutting tool to remove material as the workpiece rotates.

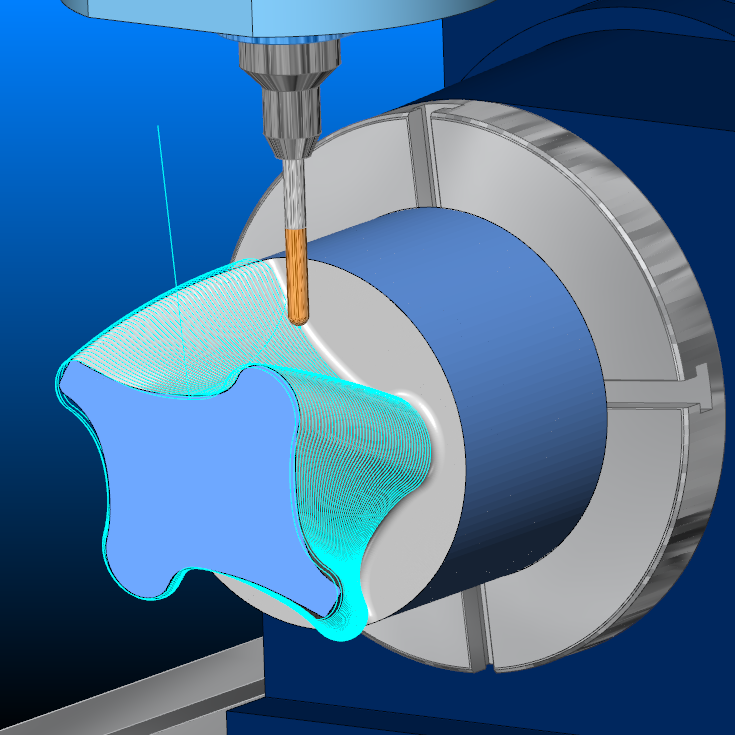

CAD/CAM

RAPID PROTOTYPING

TOOLING

CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) are essential technologies used in metal fabrication. CAD software is utilized to design and model parts, while CAM software is employed to generate the instructions necessary for the manufacturing equipment to produce the parts accurately.

Rapid prototyping is the process of quickly creating a physical model or prototype of a part or product using computer-aided design (CAD) data. This allows for testing and validation before proceeding to full-scale production.

Tooling refers to the specialized equipment and tools used in metal fabrication processes, such as molds, dies, and jigs. These tools are designed to shape and form metal into the desired configurations.

ALUMINUM AND STEEL

GASKETS

CLOSE TOLERANCE

Metal fabrication services work with various materials, with aluminum and steel being among the most common. These materials are chosen for their strength, durability, and versatility in a wide range of industrial and consumer applications.

Gaskets are components used to create a seal between two mating surfaces, preventing leakage of liquids or gases. In metal fabrication, gaskets are typically custom-made to fit specific applications and ensure proper sealing.

Close tolerance machining refers to the ability to achieve extremely precise and accurate measurements and dimensions during the fabrication process. This is crucial for applications where tight tolerances are required for proper functioning and fit.